Types of support | Flexible supports | Rigid framed supports | Fixtures and fastenings | Metal brackets | Cables

Knee braces | Dangerous things to avoid | Non-flat surfaces | Improving stability | Building without trees

Metal brackets

Metal brackets are used for both fixed and flexible joints. The main fixed situation is for fitting knee braces to a single tree in a radiating arrangement, like the spokes on a wheel. The bracket solves the awkward problem of fixing a beam by its end grain to a flat surface. Brackets like these can be made up by metal fabricators and must always be made from at least ¼" thick steel with quality welds at any joint. Getting the bracket treated to resist corrosion is advisable, although brackets tend to be protected from most rainfall due to their location under the floor.

Use only one bolt to mount each bracket

Brackets should be attached to the tree with just one bolt wherever possible to avoid problems with compartmentalisation. This bolt needs to be strong enough to sustain the forces exerted on it. You should use lag bolts that are at least 8" long and ¾" diameter.

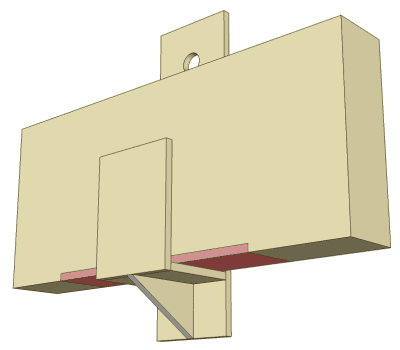

Using brackets to allow a beam to slide

These are used for spans between two points. Allow enough extra length on the beam so it can move freely in the bracket without being at risk of sliding out completely. Before fitting anything in the tree, measure the distance the beam will span, preferably on a calm day so there is no movement. Mark on the beam where one end will be bolted and where the mid-point of the sliding bracket should be. Screw a strip of ¼" thick steel measuring 2"x12" to the beam, centred on the mid-point mark. This acts as a bearing surface with the bracket to avoid grinding away the beam itself.

Mount the bracket in the tree, bearing in mind where you want the floor level to be (it will be an extra 8" or so above the surface of the bracket). Place the beam in the bracket so the metal strip is in the correct place. Use a spirit level to get the other end of the beam at the right height and temporarily fix with a screw. Now you can drill a hole for the bolt that will fix this end and secure it in place. The bolt hole should be slightly smaller than the diameter of the bolt, so it gets a tight grip when in place.

In each case a metal plate should be fitted to the underside of the beam (see red section in diagram below) to avoid damage to the beam through wear.

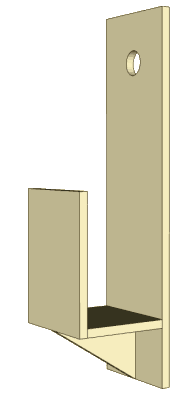

J brackets

These are the simplest to make and allow the beam to be dropped into place after the bracket has been bolted into the tree.

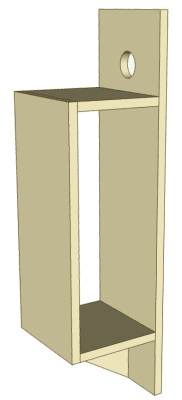

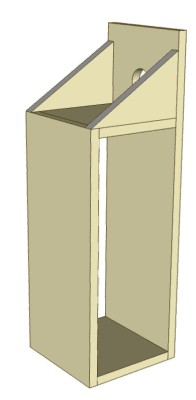

Box brackets

Stronger than the J but requires the beam is fed in from one side after fitting. You can fit them the other way around, ie slide the bracket onto the beam first, then attach the assembly to the tree, but you will need some scaffolding or temporary rope support system for this. The second design below is stronger as the triangles next to the bolt hole will prevent the bracket twisting under severe load.